When looking for a laser welder on the web, you may get quite an extensive range of prices – from as little as $4,999 up to around $10,000. But some sites seem hesitant to give out exact values and instead offer “Request Quote” options. Could it be that this industrial tool is priced differently in different markets or are there other factors at play?

To get the best possible outcome in any process, begin with accurate diagnostics. For those who are either leading the shift to Laser Welding within their business or looking for better welding practices as an individual welder – first seek out a knowledgeable expert who can not only explain Laser Welding but also understands your specific needs and goals.

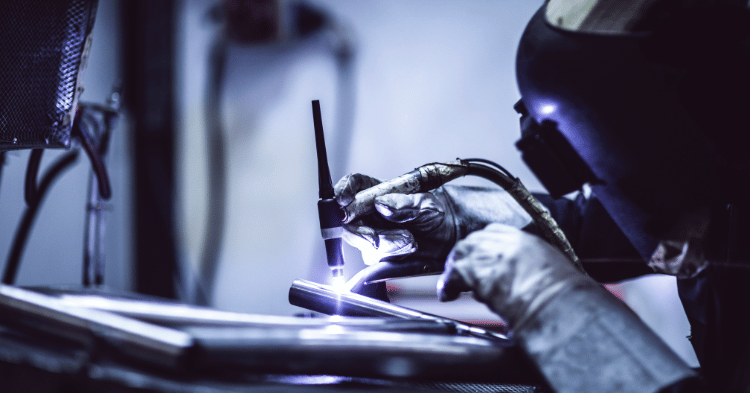

The welding process may seem like a snap, but there’s more to it than meets the eye. Ensuring efficient operations and getting ideal results requires an understanding of both pre-weld and post-weld preparation which can take several hours in total. It’s not just about finding the most powerful spot welder on the market – you’ll also need someone with expertise who understands what would be best suited for your needs. If you have experience as an engineer yourself, get down into the nitty gritty details when discussing each laser system model with their sales representative so that you know exactly how they compare in terms of strength capabilities!

After having someone who understands your pre and post-processes, you also need someone who can identify and provide solutions to your constraints.

Providing laser welding solutions to your constraints

When it comes to making the best decision for your job shop, there are multiple considerations beyond just finding a laser welder that fits in its physical constraints. Price, after-sales support, product reliability and warranty can determine cost benefits over time while adhering to regulations and safety protocols should always remain top priority. Every situation is unique but listening carefully with an informed approach will equip sales agents to make decisions based on moral interests of their clients rather than simply going for the “best” option available.

Cost, speed and quality: it’s the holy trinity of most purchases. Rarely can you identify a product or service that offers all three simultaneously–at least without sacrificing something somewhere in the process. The competitive landscape is such that even tech giants like Apple and Google struggle to balance these factors while still striving for success–so just imagine how difficult this feat would be if creating perfect harmony among them was attainable! It’s clear; finding an ideal combination of fast, cheap AND good is no easy task.

Investing in a laser welder is so much more than buying just another piece of work tool. As potential buyers, it’s important to look beyond the price tag and try to understand why one brand might be priced higher than others. After all, high-quality components sourced from experienced workers may go into designing unique products that are superior yet come with a hefty cost! The best way to evaluate product quality? Keep an eye out for secondhand or used lasers – if they’re rarely available or quickly snatched up once listed on markets then you know those models must have something special about them.

Evaluating the efficiency of lasers

For a Laser welder, there are some fundamentals, non-negotiable engineering designs that simply cannot be substituted for a cheaper alternative. For example, in an Nd: Yag source laser system, the cavity is plated with gold for maximum reflectivity and efficiency. Another plating simply does not reflect as well as gold and that is a non-deniable engineering truth. Every brand of laser welder has its trade secret that has taken years of experience to perfect it. If the product has been marketed to produce up to 1500W, make sure that you have a reliable form of evaluating and discerning the outcome of a 1500W laser.

The decision to invest in laser welding could be a difficult one, but assessing the full cost against the advantage of increased productivity or quality can help determine if this is the right approach for you. Remember, the costs for a laser welder should include far more than just the price tag! Buyers should be aware of additional expenses like freight, custom permits, and licensure if they wish to do their research thoroughly. But when all is said and done, customers can expect to pay anywhere from $30,000 USD to $150,000 USD for a state-of-the line laser welding machine.

Hopefully this has given you an idea of what kind of budget you’ll need when considering adding a laser welder to your business operations. Consider every potential cost before making any decisions and make sure that you have considered your pre-processes and constraints to determine whether or not this is the right choice for you.