Home / FAQ

What is

Laser Welding?

“Laser Welding” is a combination of terms using Laser (Light Amplification by Stimulated Emission of Radiation) and Welding(Melting and Fusion of Materials). Light energy is intensified into a concentrated and concentric path(beam) directed onto the surface of two materials- melting and fusing them together.

Why LBW over conventional Welding process such as GTAW/TIG?

1) Low Heat Input = Minimal Distortion.

2) Low Operator Skill Required – Welding with joystick.

3) Low Risk of burns, scalds and work injury.

4) Low Heat Affected Zone (HAZ)

5) Precision Control and Viewing of Weld Pool through Ergonomic Microscope.

6) Able to weld thin materials without blow through.

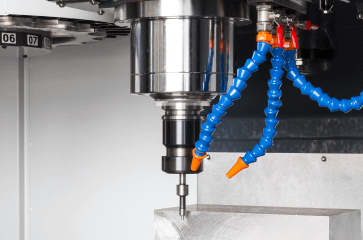

How do Laser Beam Welding (LBW) Machines or Laser Welders work?

LBW Machines uses a gain medium to excite and intensify the light energy. This beam of amplified energy is then guided to the workpiece by reflecting across delicate mirrors. The diameter of the laser beam can range from 0.2mm to 2.0mm. Aphla Lasers uses a gain medium of either a YAG crystal or Fiber Optic.

Why Laser Beam Welding?

LBW generates a very high peak power while keeping the overall heat input into the workpiece to the minimum. In laymen terms, you can place your fingers onto a 1mm spot weld after welding without feeling any heat. In technical terms, time taken from the melting and solidification of the molten metal is in milliseconds which increases the rate of heat dissipation.

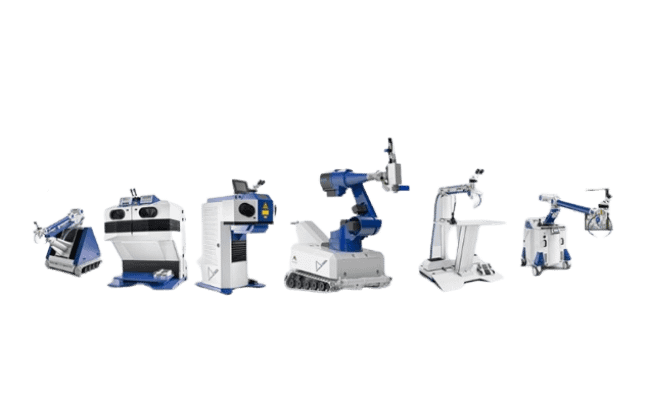

Alpha Laser

has a Micro

Welding Option

Alpha Lasers has a Micro Welding Option, allowing beam diameter to be smaller than 0.2mm. User with basic human motor skills is capable enough to produce a sound weld with Alpha Laser System.

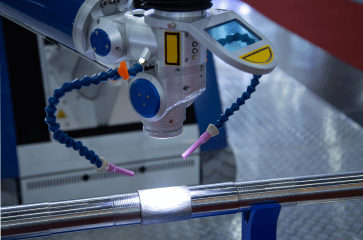

Unique Selling Point

Flexible Laser Head

- Laser beam can be bent, allowing it to reach difficult and narrow locations.

- Extra accessories can be integrated for a wide range of reach.

- Hard to reach areas are now easy.

- No longer have to worry about tilting, flipping or rotating the workpiece especially if it weighs a ton.

- Welding on keyhole and sidewall are now much easier.

- High laser beam accuracy and precision.

- Clean, Consistent and Stable generation of laser beam at high duty cycles.

Laser Weld with a Joystick between both laser photonics and mechanical movement.

- If you used to play aeroplane video games, you will adapt into the system in no time! Easy to operate precision laser.

- Excellent ergonomics coupled with software to simplify welding process. Inbuilt welding apps are integrated with laser system for easy access and usage.

- Laser photonics and movement integrated by single manufacturer. This makes trouble shooting, repair and laser welding much more refined.

- Machine is designed and improved with consideration of maintenance and practicality while retaining its reliability.

Personal Experience

- Downtime is kept to minimum due to direct service support from Germany.

- Continual relationship with laser manufacturer from Germany since 2008.

- Understands welding > machine.

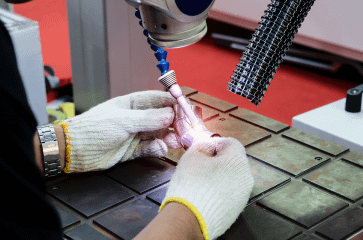

Applications of Laser Welder

Laser Beam Welding can be used for:

Metal Joining

Fusion of similar / dis-similar metals.

Metal Restoration

By building up on word or damaged surfaces or edges.

Metal Repair

Joining back two broken metals together.

Laser Beam Welding is also often used for seam or seal welding.